Retrofitting Hand Tools for Robots: A Practical Guide

Small factories face unique automation challenges. High costs and complex integration often prevent them from adopting traditional robotic solutions. However, retrofitting existing hand tools for robotic use presents a cost-effective alternative. This article explores the technical aspects of this trend, offering practical advice for implementation.

The Problem: Automation Needs in Small Factories

Many small factories still rely heavily on manual labor. This can lead to inconsistencies in product quality. It also increases the risk of repetitive strain injuries. Automating repetitive tasks can significantly improve efficiency and worker safety. But, conventional robotic systems can be prohibitively expensive. The required infrastructure upgrades and specialized programming add to the financial burden.

Small factories often have limited floor space. Large, complex robotic cells may not fit. This forces them to explore alternative automation strategies. Retrofitting hand tools offers a way to leverage existing equipment. It minimizes the need for extensive renovations. This approach also allows for a phased implementation, spreading out the investment over time.

The Trend: Robotic Tool Retrofitting

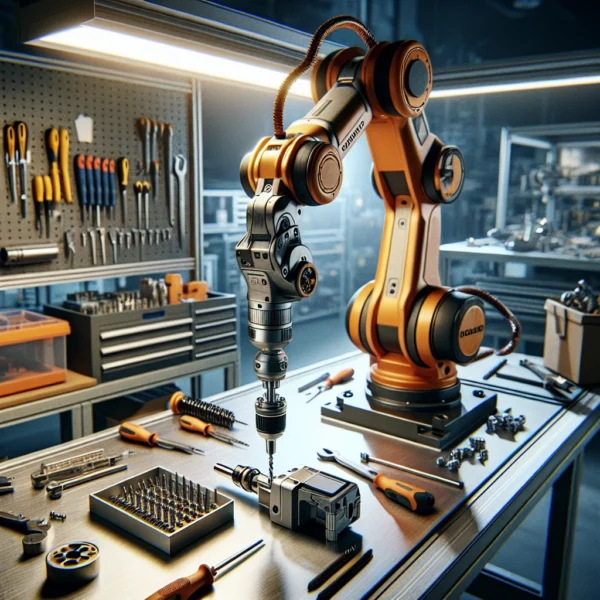

Robotic tool retrofitting involves adapting existing hand tools for use with robots. This includes tools like screwdrivers, drills, pliers, and even painting applicators. The process typically involves adding sensors, actuators, and communication interfaces to the tool. These modifications allow the robot to control the tool precisely and monitor its performance.

The core idea is to make the robot “feel” what a human operator would. Sensors provide feedback on force, torque, and position. This data allows the robot to adjust its movements in real-time. This is crucial for tasks that require delicate manipulation or precise force application. The trend is growing due to advancements in sensor technology and affordable microcontrollers.

Benefits of Retrofitting

Retrofitting offers several key advantages. First, it significantly reduces the initial investment compared to purchasing a complete robotic system. Second, it allows small factories to automate specific tasks without disrupting their entire production line. Third, it leverages the familiarity of existing tools. Operators are already familiar with how the tools work, reducing the learning curve.

Another significant benefit is the flexibility it provides. Retrofitted tools can be easily switched between different robots or tasks. This allows small factories to adapt quickly to changing production demands. Furthermore, this approach can be scaled up gradually, allowing companies to build their automation capabilities over time. Check out more about collaborative robots here.

Technical Solutions: Adapting Hand Tools

Several approaches can be used to retrofit hand tools. The specific method depends on the tool itself and the desired level of automation. However, some common elements are involved in most retrofitting projects.

First, the tool needs to be equipped with a suitable interface for the robot. This typically involves a mechanical adapter that allows the robot to grip the tool securely. The adapter should be designed to minimize vibrations and ensure precise positioning. CAD models and 3D printing are often used to create custom adapters.

Adding Sensors and Actuators

Next, sensors are added to monitor the tool’s performance. Force sensors can measure the force applied during a task. Torque sensors can measure the twisting force. Position sensors can track the tool’s location and orientation. These sensors provide critical feedback to the robot’s control system.

Actuators are used to control the tool’s operation. For example, a pneumatic cylinder can be used to activate a screwdriver. A servo motor can control the speed and torque of a drill. The choice of actuator depends on the tool’s power requirements and the desired level of control. Make sure you consider power consumption and safety requirements.

Communication and Control

Finally, a communication interface is needed to connect the tool to the robot’s control system. This interface allows the robot to send commands to the tool and receive feedback from the sensors. Common communication protocols include Ethernet, Modbus, and CAN bus. A microcontroller is often used to manage the communication and control the actuators and sensors.

Open-source platforms like Arduino and Raspberry Pi are popular choices for microcontrollers. They offer a wide range of libraries and tools for developing custom control algorithms. The control system should be designed to ensure that the tool operates safely and efficiently. Explore ROS (Robot Operating System) for control here.

Implementation Advice: A Step-by-Step Guide

Implementing a robotic tool retrofitting project requires careful planning and execution. Here’s a step-by-step guide to help you get started.

1. Identify Suitable Tasks: Start by identifying tasks that are repetitive, physically demanding, or prone to errors. These are the best candidates for automation. Consider factors like cycle time, volume, and required precision.

2. Select the Right Tools: Choose hand tools that are well-suited for robotic use. Consider the tool’s size, weight, and power requirements. Also, consider the availability of replacement parts and the ease of maintenance.

3. Design the Retrofit: Develop a detailed design for the retrofit. This includes selecting the appropriate sensors, actuators, and communication interface. Use CAD software to create a 3D model of the modified tool. Consider using simulation software to test the design before building it.

Practical Considerations

4. Build and Test the Prototype: Build a prototype of the retrofitted tool and test it thoroughly. This will help you identify any design flaws or performance issues. Use a testing fixture to simulate the actual working conditions.

5. Integrate with the Robot: Integrate the retrofitted tool with the robot’s control system. This involves writing code to control the tool and process the sensor data. Use the robot’s programming language to create a user-friendly interface for operating the tool. Always prioritize safety during the integration process.

6. Train Operators: Train operators on how to use and maintain the retrofitted tool. Provide them with clear instructions and troubleshooting guides. Encourage them to provide feedback on the tool’s performance. Continuous improvement is essential for successful automation.

7. Monitor and Maintain: Monitor the performance of the retrofitted tool and perform regular maintenance. This will help you ensure that it operates reliably and efficiently. Keep track of any problems and make adjustments as needed. Properly maintained tools can reduce downtime and increase production.

Case Studies and Examples

While real-world case studies are limited due to proprietary information, we can create hypothetical examples. Imagine a small furniture factory using manual screwdrivers for assembly. By retrofitting these screwdrivers with torque sensors and robotic interfaces, they can automate the screw-driving process. This leads to consistent torque application, reducing the risk of stripped screws and improving product quality.

Another example is a metal fabrication shop using manual grinders for finishing welds. Retrofitting the grinders with force sensors and robotic arms allows for automated weld grinding. This improves surface finish consistency and reduces worker fatigue. The possibilities are endless. The key is identifying the right tools and tasks for automation.

Safety Considerations

Safety is paramount when retrofitting hand tools for robots. Ensure that the robot’s control system includes safety features such as emergency stop buttons and collision detection. Install physical barriers to prevent workers from entering the robot’s work area. Conduct a thorough risk assessment to identify potential hazards and implement appropriate safeguards. Adhere to relevant safety standards and regulations. Learn more about robotic safety here.

Conclusion: Embracing Affordable Automation

Retrofitting hand tools for robots offers a viable path to automation for small factories. It provides a cost-effective way to improve efficiency, reduce errors, and enhance worker safety. By carefully planning and executing the retrofit process, small factories can leverage the power of robotics without breaking the bank. As technology advances, robotic tool retrofitting will become even more accessible and widespread. This trend has the potential to revolutionize manufacturing in small businesses worldwide.

🛠️ $5,000 Tool for your Cobot?

Why overspend? Turn hand tools you already own into precision cobot tools.

Our universal adapters let you mount standard grinders, sanders, and drills to your collaborative robot in minutes.

Leave a Reply