Cost-Effective Techman Robot Automation for Small Factories

Small factories often face challenges. These include limited budgets and resources. Automation seems expensive. However, collaborative robots (cobots) like Techman Robots offer a solution. They provide a cost-effective way to improve efficiency and productivity. This article explores how small factories can leverage Techman Robots for automation. We will discuss implementation strategies and real-world examples.

The Automation Problem for Small Factories

Small factories struggle with several issues. Skilled labor is hard to find. Production costs are high. Competition is fierce. Traditional automation solutions are often too expensive. They also require extensive programming and specialized expertise. This makes automation inaccessible for many small businesses.

Manual labor dominates many processes. This leads to inconsistencies and errors. Employees perform repetitive tasks. These tasks are often ergonomically challenging. This results in fatigue and potential injuries. Automation can alleviate these problems.

Many small factories believe automation is complex. They think it requires significant capital investment. They also fear disrupting existing operations. This perception hinders their ability to compete. They miss opportunities to improve efficiency and profitability.

The Collaborative Robot Solution

Collaborative robots offer a different approach. They are designed to work safely alongside humans. Cobots are easier to program and deploy than traditional industrial robots. Techman Robots are particularly well-suited for small factories. They offer a range of models with varying payloads and reach. They are also known for their user-friendly interface and integrated vision systems.

Techman Robots provide flexibility. They can handle a variety of tasks. These tasks include pick and place, assembly, machine tending, and quality inspection. Their compact size allows them to fit into existing workspaces. This reduces the need for significant infrastructure changes.

Their intuitive programming interface simplifies integration. Workers can easily learn to operate and maintain the robots. This reduces the need for specialized robotic expertise. This makes Techman Robots a viable option for small factories with limited technical resources.

Techman Robot: Features and Benefits

Techman Robots boast several key features. These features contribute to their cost-effectiveness. Integrated vision systems allow for precise object recognition and manipulation. This eliminates the need for external cameras and complex programming.

Their user-friendly interface simplifies programming. Operators can use drag-and-drop commands to create robot programs. This reduces the learning curve and allows for faster deployment. Built-in safety features ensure safe operation alongside human workers. Force sensors detect collisions and automatically stop the robot.

The robots are energy-efficient. They consume less power than traditional industrial robots. This reduces operating costs and promotes sustainability. Their compact design saves valuable floor space. This is crucial for small factories with limited room.

Cost Considerations and ROI

The initial investment in a Techman Robot is significant. However, consider the long-term return on investment (ROI). Automation reduces labor costs. It also increases production output. Furthermore, it improves product quality. These factors contribute to a faster ROI. Techman Robot Product Line

A detailed cost-benefit analysis is crucial. Factor in the cost of the robot, installation, programming, and training. Also, consider the savings in labor, material waste, and production time. Calculate the increase in output and the improvement in product quality. This will provide a clear picture of the potential ROI.

Explore financing options. Leasing programs and government grants are available. These options can help reduce the upfront investment. Consider starting with a single robot for a specific task. This allows you to evaluate the benefits before investing in additional robots. ROI of Collaborative Robots

Implementation Advice for Small Factories

Successful implementation requires careful planning. Start by identifying specific tasks that can be automated. Choose tasks that are repetitive, physically demanding, or prone to errors. Machine tending and packaging are good candidates.

Develop a detailed automation plan. This plan should outline the project goals, budget, timeline, and resources. Select the appropriate Techman Robot model for the task. Consider the payload, reach, and required precision.

Provide adequate training for your employees. Train them on robot operation, programming, and maintenance. This will ensure they can effectively utilize the robot and troubleshoot any issues. Cobot Integration Tips

Safety First: Risk Assessment and Mitigation

Safety is paramount. Conduct a thorough risk assessment. Identify potential hazards associated with robot operation. Implement appropriate safety measures. These measures include safety fences, light curtains, and emergency stop buttons. Ensure the robot is properly integrated with existing machinery.

Train employees on safety protocols. Emphasize the importance of following safety procedures. Regularly inspect the robot and safety equipment. Maintain a safe working environment. This will prevent accidents and injuries.

Consider using collaborative features. Techman Robots offer collaborative features that enhance safety. Force sensors detect collisions. They automatically stop the robot. Speed and force limits reduce the risk of injury. Use these features to create a safe and collaborative workspace.

Case Studies and Real-World Examples

Many small factories have successfully implemented Techman Robot automation. They have seen significant improvements in efficiency and productivity. Unfortunately, specific case studies with detailed metrics are not available without proprietary information. However, general examples illustrate the potential.

Consider a small metal fabrication shop. They use a Techman Robot for machine tending. The robot loads and unloads parts from a CNC machine. This frees up human workers for more skilled tasks. It also increases the machine’s utilization rate.

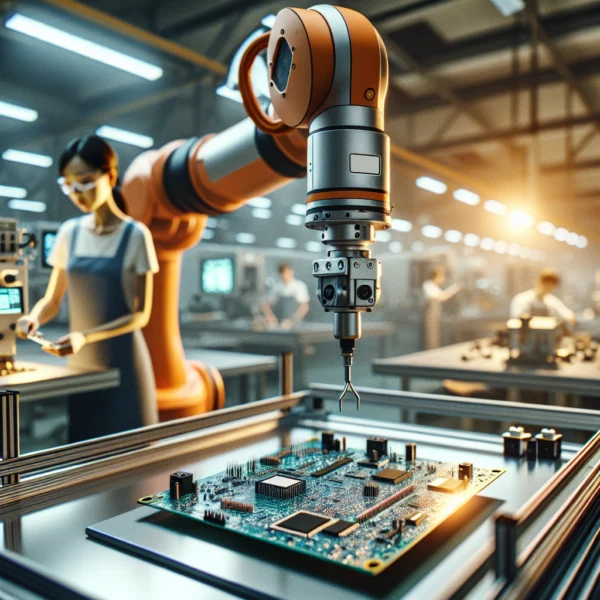

Another example is a small electronics assembly factory. They use a Techman Robot for pick-and-place operations. The robot places components onto circuit boards. This improves accuracy and reduces assembly time. The reduction of errors pays for the initial investment.

Looking Ahead: The Future of Automation for Small Factories

The future of automation is bright. As technology advances, robots will become even more affordable and easier to use. Artificial intelligence (AI) will play a larger role. It will enable robots to perform more complex tasks. Cloud connectivity will enable remote monitoring and control.

Small factories should embrace automation. It is a key to staying competitive. By leveraging Techman Robots and other collaborative technologies, they can improve efficiency, reduce costs, and enhance product quality. This will allow them to thrive in an increasingly competitive global market.

Start small, learn quickly, and adapt continuously. This is the key to successful automation for small factories. Don’t be afraid to experiment and embrace new technologies.

Conclusion: Techman Robots Empowering Small Factories

Techman Robots offer a compelling solution for small factories seeking cost-effective automation. Their user-friendly interface, integrated vision systems, and collaborative features make them accessible to businesses with limited resources. By carefully planning and implementing automation projects, small factories can unlock significant benefits, improve their competitiveness, and secure their future.

They can also enhance worker safety and morale. Manual, repetitive tasks are taken on by robots. This allows humans to focus on more engaging and fulfilling work.

Ultimately, Techman Robot automation empowers small factories. It allows them to achieve more with less and compete effectively in the global marketplace. Investigate your options today.

🛠️ $5,000 Tool for your Cobot?

Why overspend? Turn hand tools you already own into precision cobot tools.

Our universal adapters let you mount standard grinders, sanders, and drills to your collaborative robot in minutes.

Leave a Reply