body { font-family: sans-serif; }

h2, h3 { color: #333; }

p { line-height: 1.6; }

Cost-effective Universal Robots Automation for SME Retrofit

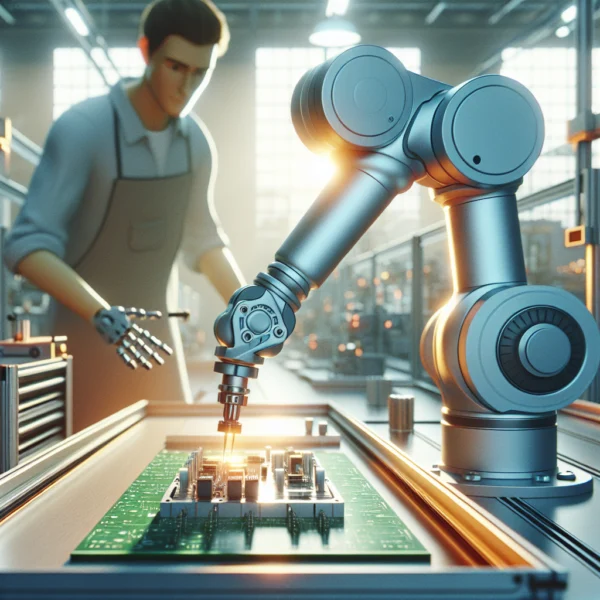

Small and medium-sized enterprises (SMEs) often face challenges. They need to improve productivity. They also have limited budgets. Automation offers a solution. Universal Robots (UR) provide a compelling option. They are collaborative robots, or cobots. Cobots are designed to work alongside humans. They are more accessible than traditional industrial robots.

The Automation Problem for SMEs

Many SMEs rely on manual labor. This can lead to inefficiencies. It also leads to quality variations. Traditional industrial robots are expensive. They also require significant infrastructure. This makes them unsuitable for many SMEs. The cost of integration is also a barrier. Skilled programmers and dedicated safety systems are required. SMEs need a more affordable and flexible solution.

SMEs are looking for quick returns on investment. They want to automate tasks. Tasks like pick and place, assembly, and machine tending are ripe for automation. The problem is finding a cost-effective way to do it. Minimizing downtime during the retrofit is also critical.

Why Universal Robots for SME Automation?

Universal Robots offer several advantages. They are relatively inexpensive. They are also easy to program and deploy. Their collaborative nature allows them to work safely alongside humans. This reduces the need for extensive safety guarding. This reduces overall costs. UR robots are also lightweight and flexible. They can be easily moved and repurposed. This provides a high degree of adaptability.

The UR ecosystem is robust. It includes a wide range of end-effectors and software. This makes it easier to find solutions for specific applications. The intuitive programming interface reduces the need for specialized programming skills. This further lowers the barrier to entry for SMEs.

Universal Robots: A Technical Overview

UR robots are six-axis articulated robots. They use direct drive joints. This provides excellent precision and repeatability. Force/torque sensing is integrated. This allows for sensitive manipulation. It also provides enhanced safety. The control system is based on a real-time operating system. It ensures predictable performance.

The programming interface is based on a graphical user interface. This is called PolyScope. Users can create programs using drag-and-drop commands. They can also use a script-based language for more complex tasks. The UR Academy provides free online training. This helps users get started with programming.

Key Technical Specifications

UR offers different models. They offer varying payloads and reach. Common models include the UR3e, UR5e, UR10e, and UR16e. The “e-Series” robots incorporate advanced safety features. They include adjustable safety functions. These functions are compliant with ISO/TS 15066. Typical payloads range from 3 kg to 16 kg. Reach ranges from 500 mm to 1300 mm. Repeatability is typically ±0.03 mm.

Power requirements are typically 24V DC or 100-240V AC. Communication interfaces include Ethernet, Modbus TCP, and PROFINET. This allows for easy integration with existing factory networks. The robots also support a variety of end-effectors. These include grippers, vision systems, and force sensors. See Universal Robots’ technical specifications: Universal Robots Product Line.

Retrofitting an SME with UR Robots: Implementation Advice

Successful UR robot implementation requires careful planning. It also requires execution. Begin with a thorough assessment of your needs. Identify specific tasks that can be automated. Consider factors such as cycle time, throughput, and quality requirements.

Choose the right robot model. Select one based on payload and reach requirements. Select end-effectors carefully. Consider the materials being handled. Consider the required precision. Look into vendors specializing in UR integration. They can provide valuable support.

Step-by-Step Implementation Guide

- Needs Assessment: Identify target processes. Quantify potential benefits.

- Robot Selection: Choose the appropriate UR model. Consider payload and reach.

- End-Effector Selection: Select grippers, vision systems, or other tools. Ensure compatibility.

- Workcell Design: Design the robot’s workspace. Ensure safety. Consider ergonomics.

- Programming: Program the robot using PolyScope. Test the program thoroughly.

- Safety Integration: Implement safety measures. Ensure compliance with safety standards.

- Training: Train employees on robot operation and maintenance.

- Monitoring and Optimization: Monitor robot performance. Optimize the program for efficiency.

Safety is paramount. Perform a risk assessment. Implement appropriate safety measures. These measures may include safety scanners, light curtains, and emergency stop buttons. Ensure that all personnel are properly trained on safety procedures. See OSHA guidance on collaborative robots: OSHA Robotics Safety.

Cost Considerations and ROI

The cost of a UR robot varies. It depends on the model and accessories. The initial investment includes the robot, end-effectors, and integration costs. Ongoing costs include maintenance and training. Consider leasing options. They can reduce the initial capital outlay.

Calculate the return on investment (ROI). Consider factors such as increased productivity, reduced labor costs, and improved quality. A well-planned UR robot implementation can provide a quick ROI. It can significantly improve your bottom line.

Case Studies and Examples

Many SMEs have successfully implemented UR robots. They have achieved significant improvements. One example is a small manufacturing company. They automated a pick-and-place task. They reduced cycle time by 50%. They also improved product quality.

Another example is a machine shop. They used a UR robot for machine tending. They increased machine utilization. They also freed up human workers for other tasks. These examples demonstrate the potential benefits of UR robot automation for SMEs. Consider visiting industry events. Network with other users. Learn from their experiences.

Real-World Applications

- Pick and Place: Automating repetitive tasks. Improving speed and accuracy.

- Assembly: Assisting with assembly operations. Reducing errors.

- Machine Tending: Loading and unloading machines. Improving machine utilization.

- Quality Inspection: Inspecting parts for defects. Ensuring quality control.

- Packaging: Automating packaging processes. Increasing throughput.

Conclusion: The Future of SME Automation with UR Robots

Universal Robots offer a cost-effective automation solution for SMEs. They are flexible, easy to program, and safe to operate. By carefully planning and implementing a UR robot solution, SMEs can improve productivity, reduce costs, and enhance quality. As robot technology continues to advance, UR robots will become even more accessible and powerful. This will drive further adoption in the SME sector.

The key is to start small. Pilot a project with a clearly defined objective. Learn from the experience. Gradually expand automation to other areas of your business. Embrace the potential of collaborative robots. Transform your SME into a more efficient and competitive organization. Review integration best practices from the Robotic Industries Association: Robotic Industries Association.

🛠️ $5,000 Tool for your Cobot?

Why overspend? Turn hand tools you already own into precision cobot tools.

Our universal adapters let you mount standard grinders, sanders, and drills to your collaborative robot in minutes.

Leave a Reply